How to mix concrete at site? Mixing Type?

Type of concrete mixing at Site

- Manual Mixing

- Machine Mixing

Concrete mixing is very important for the good strength of the structure.

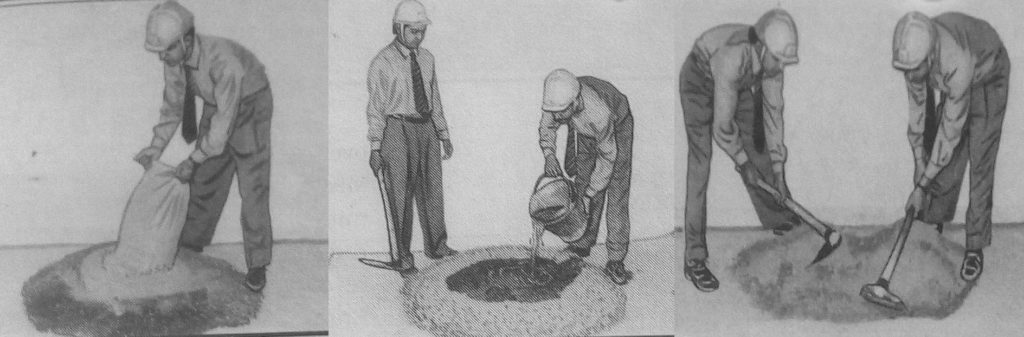

Hand Mixing Concrete.

- Check the platform before mixing At the time of mixing ensure that no cement slurry flows away.

- Using M.S. trays if a concrete platform in not available.

- Check the proportion of sand, metal, and cement for one bag mix. Measurement should be taken by farma only.

- Prepare one bag mix at a time.

- Dry materials are mixed by turning them over, from one end to another and cutting with a shovel until the mix appears uniform.

- Turning is done three times for dry mix material, for proper mixing.

- Make a pond required size and dry material for water.

- Add an approx. quantity of water slowly to the dry mix, using a bucket. Check the capacity of the bucket.

- Mix all the materials until a uniform colour and consistency appear.

- After Visual inspection, if the colour and consistency of concrete do not seem right add 10% more cement in the same mix.

Machine Mixing

Machine mixing is faster and cheaper than hand mixing. It generally produces more strength and better workability.

Type of machine mixing.

- Tilting Mixer

- Pan Mixer

- Non-Tilting Mixer

Tilting mixer is used more often.

- Clean the hopper first.

- Place the coarse aggregate first in the hopper followed by sand and cement.

- Check if the correct quantities of cement, sand and aggregate are loaded in the hopper or not.

- Raise the hopper to discharge the material into the rotating drum.

- Add the correct amount of water to the drum using a bucket.

- The period of mixing in the rotating drum should be 1-2 minutes.

Advantage of machine mixing Concrete.

- The water-cement ratio can be controlled easily in machine mixing.

- All materials like cement, sand metal etc, can be mixed properly.

- Easily control over mixing i.e. up to the required colour and consistency.

- Wastage of cement, sand and metal can be reduced with the hopper.

- For larger concreting works, the strength of labour is reduced.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|