What is Scaffolding & Different Types of Scaffoldings?

What is Scaffolding?

Scaffolding is also known as scaffold or staging. It is a temporary and elevated erection on the outer side of a structure, made for working labours and materials to be shifted from one place to another. These are made up of wooden planks and metal pipes. Staging is used where it is hard to reach in order to complete a task such as plaster work. While it is a temporary structure it needs high safety measures and precautions.

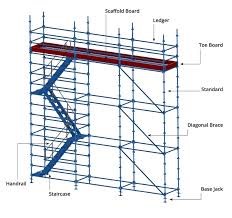

Components of different Scaffoldings:-

- A load-bearing base for the Staging: Base Jack or Plate.

- A vertical component with connector joints: The standard.

- A horizontal brace: The ledger.

- A horizontal cross-section load-bearing component that holds the batten: The transom.

- A cross section bracing component: Brace diagonal.

- A board decking component to make the working platform: Batten.

- A fitting used to join components together: Coupler.

- To tie in the scaffold to structure: Scaffold tie.

- To extend the width of working platforms: Brackets.

Types of Scaffolding:-

Different works require different kind of scaffolding. Some of the types of Scaffold are given below:

1- Trestle Scaffolding:-

Trestle scaffold have movable tripod like ladder system. Trestles are generally used for in-house works like painting, repairing. This is only used for indoor tasks because these scaffold can only be raised till 5 metres. This is also known as “Ladder Scaffold”.

2- Steel Scaffolding:

Steel scaffoldings are made up of steel tubes or poles which are connected using couplers. Steel scaffolding is very easy to install and easy to remove. This type of scaffold is a bit costlier but it is safe to work with during construction on site and is most commonly used. Steel provides better strength, durability and fire resistance and hence used for large structures.

3- Patented Scaffolding:

Patented scaffoldings are also made up of steel but they are manufactured beforehand and brought to the site for installation. They need special fixture and couplings to fit the scaffolding. In patented scaffold, working stand is arranged on supports and can be adjusted at the required level.

4- Suspended Scaffolding:

Suspended scaffolding is the one in which working platform is hanged or suspended using ropes, chains or any other non-rigid, overhead support. They are usually used for painting or repairing work because the platform can be adjusted to the required level anytime.

5- Cantilever Scaffolding:

This is also known as needle scaffold. It is not very popular because it needs various checks before the installation. In this scaffold system, a series of needles, that have been pulled out from the holes in wall, is used to support standards. This is known as Single Frame scaffolding.

There’s another type of cantilever scaffolding, in which the needles are strutted inside the floors by means of openings, this is known as Double Frame Scaffolding or Independent scaffold.

6- Single Scaffolding:

Single scaffolding is mainly used for brickwork and is also called as Bricklayers scaffold. This is the oldest method of scaffold which is still very popular. The components required for this scaffolding are standards, putlogs, ledgers, which are linked to the wall maintaining a distance of 1.2 meters. The Ledgers connect the standards at a vertical distance of 1.2 to 1.5 metres whereas the distance between the standards is 2 to 2.5 meters and the Putlogs are fixed at a distance of 1.2 to 1.5 meters.

7-Double Scaffolding:

This is also known as Mason’s Scaffolding or Independent Scaffold as it is mainly used for the stone masonry work. Supporting the putlogs for stone masonry work is very difficult because holes cannot be made in the stone walls, hence double scaffoldings are put together to create a strong structure for construction work. The first row is kept 20 to 30 cm away from the wall and the second one is kept 1 meter away from the first row. Putlogs are placed with the support of both frames.

8- Kwikstage Scaffolding:

This Scaffolding is manufactured from galvanized steel. It is very easy to install as well as to disintegrate. Hence, it is used for both large and small construction works. Kwikstage Scaffold creates safe interlocking system and strong working platform and is durable.

Regulations for scaffoldings Fixing

- All scaffolds should be constructed according to the manufacturer’s instructions,

- All open sides and ends of platforms should be installed with guardrail systems,

- There should be safe access to scaffold platforms,

- Do not use cross-bracing as a means of access.

- To design tube and coupler scaffolds that exceed the standard limits, a licensed professional engineer should be referred to,

- All the scaffolds should be erected, moved, and dismantled under the supervision of a competent person.

Visit our ![]() Channel for more information.

Channel for more information.