Different Types of Bricks Based on Its Functionality.

Types of Bricks

There are many types of bricks based on their functionality. Bricks can be used for several purposes, such as:

- Face work / Elevation Bricks.

- Partition wall.

- Brick columns.

- Supporting wall / Load Bearing Walls, and so on.

Other than their functionality, bricks can also be classified based on the material used to prepare them. Following are the general bricks that are being used around the world:

1- Acid Resistant Bricks:

These are special type of bricks which are designed specifically for chemical plants. They are used to resist harmful chemicals and make the wall thermally durable. They are made up of refractory clay, felspar and a small amount of silica.

2- Engineering Bricks:

Engineering bricks are denser because they are manufactured under very high temperatures. Thus, these bricks are capable of withstanding the heat. Engineering bricks are used for better strength, frost resistance, acid resistance, and low porosity. They are used for sewers, manholes, basements, and retaining walls.

Engineering bricks are denser because they are manufactured under very high temperatures. Thus, these bricks are capable of withstanding the heat. Engineering bricks are used for better strength, frost resistance, acid resistance, and low porosity. They are used for sewers, manholes, basements, and retaining walls.

3- Silica Bricks:

As its name suggests, silica bricks contain a high percentage of silica which improves its refractoriness. They contain about 95-97% silica and 1-2% of lime as a binding material. These bricks are used to withstand heat up to about 2000°C. They can be used for chimneys, carbonization chambers, and combustion chambers.

As its name suggests, silica bricks contain a high percentage of silica which improves its refractoriness. They contain about 95-97% silica and 1-2% of lime as a binding material. These bricks are used to withstand heat up to about 2000°C. They can be used for chimneys, carbonization chambers, and combustion chambers.

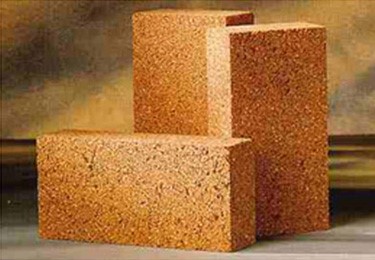

4- Refractory Bricks:

It is also known as fire bricks because they can withstand up to 1000°C. It is manufactured using a special type of earth. Refractory bricks withstand very high temperature without disturbing their shape, size, and strength. Because it has heat withstanding qualities it is used in chimneys and furnaces.

It is also known as fire bricks because they can withstand up to 1000°C. It is manufactured using a special type of earth. Refractory bricks withstand very high temperature without disturbing their shape, size, and strength. Because it has heat withstanding qualities it is used in chimneys and furnaces.

5- Sand-lime Bricks:

They are also known as calcium silicate bricks because their main constituents are sand, lime, and fly ash. Sand-lime bricks can carry their own weight and thus they are used for ornamental works of the building.

They are also known as calcium silicate bricks because their main constituents are sand, lime, and fly ash. Sand-lime bricks can carry their own weight and thus they are used for ornamental works of the building.

6- Blue Bricks:

Blue bricks are made up of clay containing 7-10% of iron oxide. These bricks are burnt at 1250°C before delivered to be used. Blue bricks are very hard, strong and dense which makes them suitable for heavy construction work such as bridge.

Blue bricks are made up of clay containing 7-10% of iron oxide. These bricks are burnt at 1250°C before delivered to be used. Blue bricks are very hard, strong and dense which makes them suitable for heavy construction work such as bridge.

7- Coloured Bricks:

These bricks are manufactured using different admixtures, Class C fly ash and water. Coloured bricks are used for attractive facing work and energy conservation. They are rarely used in India.

These bricks are manufactured using different admixtures, Class C fly ash and water. Coloured bricks are used for attractive facing work and energy conservation. They are rarely used in India.

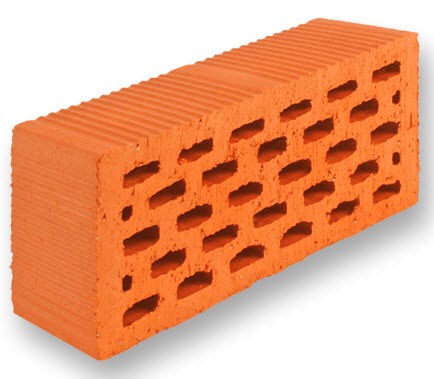

8- Perforated Bricks:

These types of bricks contain different shapes of holes throughout their thickness. These holes make them lighter in weight and less amount of clay is required to prepare perforated bricks. They are used for multi-storey framework and lightweight designs.

These types of bricks contain different shapes of holes throughout their thickness. These holes make them lighter in weight and less amount of clay is required to prepare perforated bricks. They are used for multi-storey framework and lightweight designs.

9- Hollow Bricks:

They are also called Cellular bricks or Cavity bricks. They are manufactured using a homogeneous clay leaving cavities throughout the thickness which makes them light in weight. Hollow bricks have the quality to resist sound, heat and dampness. They are generally used for partition.

They are also called Cellular bricks or Cavity bricks. They are manufactured using a homogeneous clay leaving cavities throughout the thickness which makes them light in weight. Hollow bricks have the quality to resist sound, heat and dampness. They are generally used for partition.

10- Fly-ash Bricks:

Fly ash bricks are manufactured using fly ash and water moulded at high temperature. They contain a high percentage of Calcium Oxide which is used to make cement. Hence, they are also known as Self-cementing bricks. Fly ash brick is a fine powder thrown out of thermal plants which are then used to make bricks. They are also environmentally friendly because they reduce carbon emission.

Fly ash bricks are manufactured using fly ash and water moulded at high temperature. They contain a high percentage of Calcium Oxide which is used to make cement. Hence, they are also known as Self-cementing bricks. Fly ash brick is a fine powder thrown out of thermal plants which are then used to make bricks. They are also environmentally friendly because they reduce carbon emission.

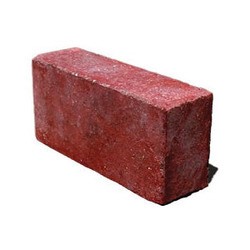

11- Burnt Clay Bricks:

Burnt clay bricks are good quality bricks made by moulding clay, placing them into a kiln and heating. Some of these bricks may be defective. For this reason, they are divided into four types:

- First Class Bricks:

First class bricks are table moulded, burnt in large kilns, sound and uniform in shape. They have a crack-free surface and are very hard. They are used for facing work mostly.

First class bricks are table moulded, burnt in large kilns, sound and uniform in shape. They have a crack-free surface and are very hard. They are used for facing work mostly. - Second Class Bricks:

Second class bricks are ground moulded, burnt in clamps. They are a bit irregular in shape as compared to the previous type. They are moderate in quality.

Second class bricks are ground moulded, burnt in clamps. They are a bit irregular in shape as compared to the previous type. They are moderate in quality. - Third Class Bricks:

These are also ground-moulded and burnt in clamps but are very irregular in shape. They have a rough surface and broken edges. These bricks are a little softer and used for temporary works.

These are also ground-moulded and burnt in clamps but are very irregular in shape. They have a rough surface and broken edges. These bricks are a little softer and used for temporary works. -

Fourth Class or Overburnt Bricks:

Fourth class bricks are also known as Jhama Bricks. 4th Class bricks are overly burnt. They have very irregular surface, hard and dark colour. They are used for foundations, roofs, floors etc.

Fourth class bricks are also known as Jhama Bricks. 4th Class bricks are overly burnt. They have very irregular surface, hard and dark colour. They are used for foundations, roofs, floors etc.

12- Unburnt Clay Bricks:

These are sun-dried bricks. They are moulded and directly dried under sunlight. They are not very durable and are used for temporary structures.

These are sun-dried bricks. They are moulded and directly dried under sunlight. They are not very durable and are used for temporary structures.

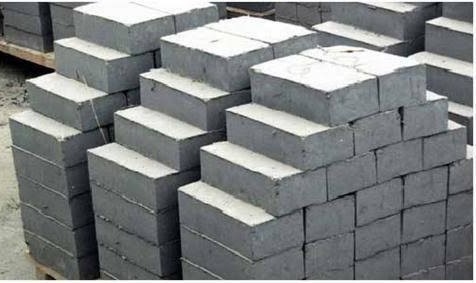

13- Concrete Bricks:

They are uniform bricks manufactured using concrete. They can be of different sizes as per the requirement. These bricks are used above and below the damp proof course. Concrete bricks are sound resistant and heat resistant which makes them suitable to be used for internal brickwork, facades etc. It is also called mortar brick. They cannot be used below ground.

They are uniform bricks manufactured using concrete. They can be of different sizes as per the requirement. These bricks are used above and below the damp proof course. Concrete bricks are sound resistant and heat resistant which makes them suitable to be used for internal brickwork, facades etc. It is also called mortar brick. They cannot be used below ground.

|

|

|

|

|

|

|

|

|

|

|

|

Visit our ![]() Channel for more information.

Channel for more information.

Amit Sah