What Is Segmental Bridge? How Segmental Bridge Construct?

WHAT IS SEGMENTAL BRIDGE?

A Segmental Bridge is a bridge built in short sections (called segments), that is one piece at a time, and then segments are erected to make the bridge. The bridge is either cast-in-place or precast.

ADVANTAGES OF SEGMENTAL BRIDGE

- Very economical for long spans.

- Prefabricated segments provide more quality control.

- The structure can be fully loaded immediately after being pre-stressed.

- The pre-stressed cables can be inspected and replaced at all times.

- Low weight due to thin bridge sections.

- Industrialization of the construction process.

- Innovations in construction equipment.

- Low maintenance costs.

- Speed of construction, time taken less

DISADVANTAGES OF SEGMENTAL BRIDGE

- High construction loading or high technology is used.

- Need high safety precautions during construction

- Extra cost (due to more pre-stressing required)

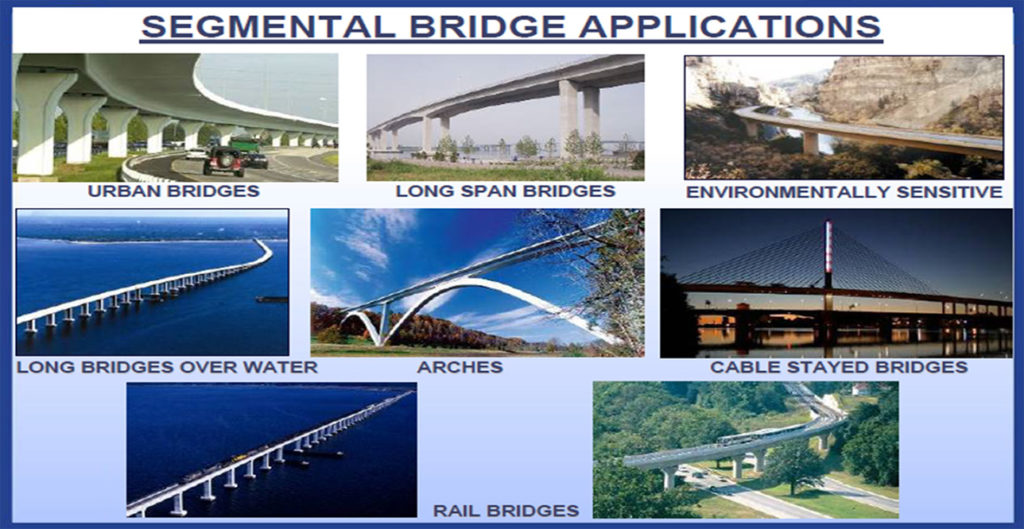

Segmental bridges are classified under the following Categories.

- Balance Cantilever Bridges

- Progressive Placement Bridges

- Span-by-Span Constructed Bridges

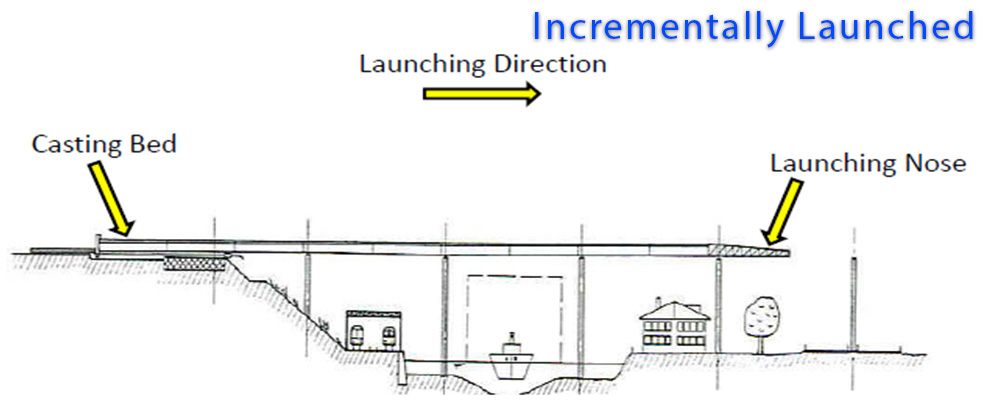

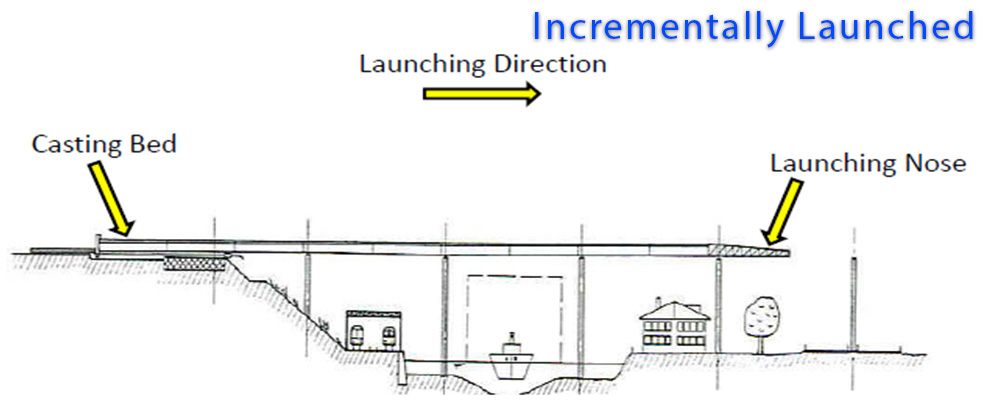

- Incrementally Launched Bridges.

Construction of segmental Bridges

The following steps are used for the construction of Segmental bridges.

- Casting of Segments

Two method used for casting of segments

- Short Line Method

In this rate of segment production is slow. Three or four segments cast at a time.

- Long Line Method

In this rate of segment production is fast. Segments equal to one span cast at a time.

After casting the segments are stored at staking yard and curing of segments will be done.

- Transfer the segment at erection site.

After casting or curing of segments are transferred at erection site with the help of traveler or crane.

- Erection of the segments:

The precast segments are erected on the sites by following erection methods.

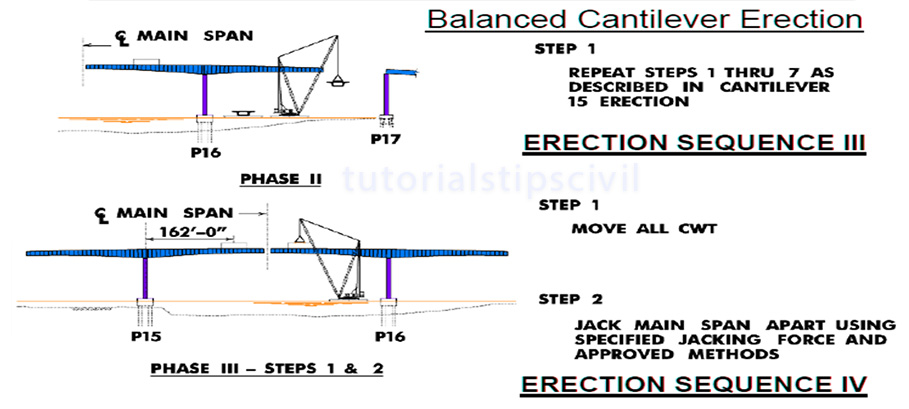

- Balanced Cantilever erection

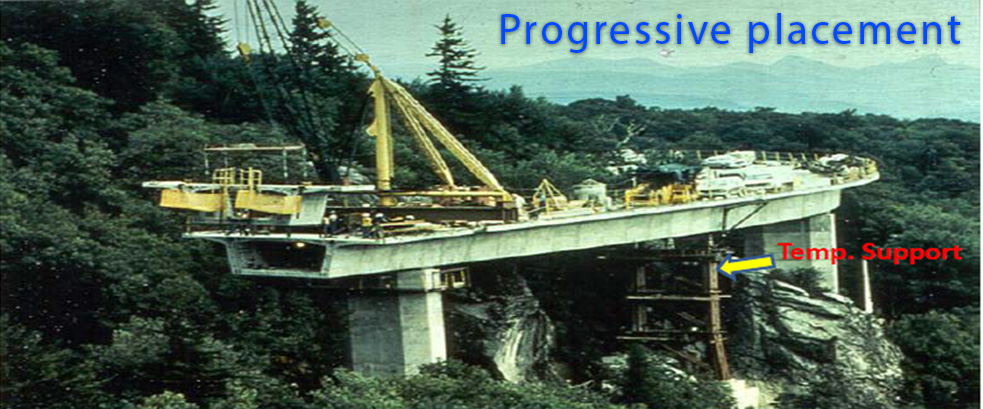

- Progressive Placement erection

- Span by Span erection

- Incremental Launching erection

High Machinery are used for the erection of segments some of the following.

- Launching Truss & accessories

- Launching girder & accessories

- Gantry crane or other cranes

- Hydraulic jacks

- Travelers.

- Epoxy Glueing

In between the two segments epoxy Glueing is used to prevent the leakage of grout during grouting.

- External per-stressing

Used for giving the final strength to bridge.

- Pre-tension method

- post tension method

- Grouting

The main purpose of grouting is to protect the all strands against corrosion and develop the bond between prestressing steel and surrounding concrete.

You Have To Know More About Civil Engineering