What is Mivan Technology? Advantage & Disadvantage of Mivan Shuttering.

Mivan Technology

Monolithic construction has been rapidly booming around the globe because of many advantages. Mivan technology is one of those methods which helps you have desired outcomes. This technology is not very popular in India but is very popular in Gulf countries, Europe, and some parts of Asia.

What is Mivan Technology?

Mivan technology uses an aluminium formwork structure which helps us construct various structural elements simultaneously. Mivan Technology is named after a European construction firm, Mivan Company Ltd. which came up with this method. Formworks of mivan consist of strong and robust aluminium components that are durable and easy to install and are used for large-sized construction within less time.

Components of Mivan Formwork:

1- Wall Components:

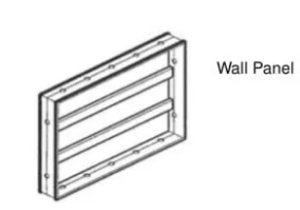

- Wall Panel

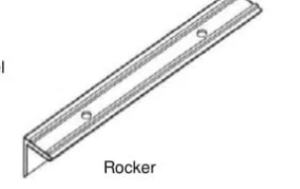

- Rocker

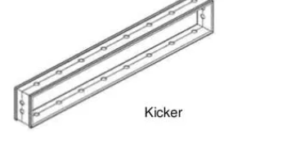

- Kickers

- Stub pin

Wall Panel

Rocker

Kicker

Stub Pin

2- Beam Components:

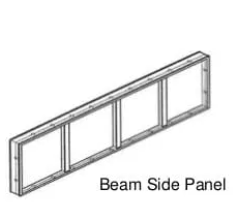

- Beam Side Panel

- Prop Head

- Panel for Soffit Beam

- Beam Soffit Bulkhead

3- Deck Components:

- Deck Panels

- Deck Prop

- Prop Length

- Soffit Length

- Deck Mid Beam

4- Other Components:

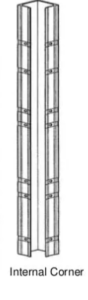

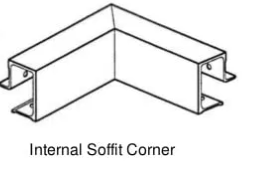

The other elements that are used are internal and external soffit corners, and exterior and interior edges for wall panels.

- External Corner

- Internal Corner

- Internal Soffit Corner

- External Soffit Corner:

Advantages of MIVAN:

- It requires comparatively less labour.

- Rapid construction and less time-consuming.

- Reduced number of joints.

- Panels can be reused 250 times.

- It can carry heavy loads (7-8 tonnes per Sqm)

- Even finishing of wall and slab.

- Vertical formwork can be struck down after 12 hours of concreting.

- Less maintenance.

- Very durable.

- More seismic resistance.

- Good quality construction work.

- No need for plastering.

Disadvantages of MIVAN:

- The alignment of formworks needs skilled labourers.

- Initial setup is time-consuming.

- It is expensive.

- It is used for typical floors only.

- Construction joints should be set meticulously.

- Leakage issues like seepage, and leakages during monsoon.

Construction steps using Mivan Formwork:

- A prefabricated steel mesh is prepared in a factory which is brought on the site and is installed for reinforcing the whole structure which acts as a support to the concrete until it gains 50% of the design strength.

- Along with the wall steel mesh, wall panels and floor slabs are erected.

- Plumb, level and alignment are checked.

- Openings for windows, doors, ducts etc are left.

- All the formwork is then connected using pins and a wedge system, which can be dismantled soon after pouring concrete.

- Concrete is poured after successfully installing the formwork.

- Pins, wedges and props are taken care of during concreting.

- Generally, after 12 hours of concreting, vertical elements are struck down.

- Removed formwork is scrapped and cleaned properly.